In the realm of advanced machining, precision and versatility are paramount. The emergence of 5-axis high-accuracy CNC milling has revolutionized the manufacturing landscape, enabling intricate and complex designs to come to life with unparalleled precision. This article delves into the world of 5-axis CNC milling, highlighting its significance and its application in machining stainless steel, brass, aluminum, and titanium.

The Evolution of CNC Machining: A Glimpse into 5-Axis High-Accuracy Milling

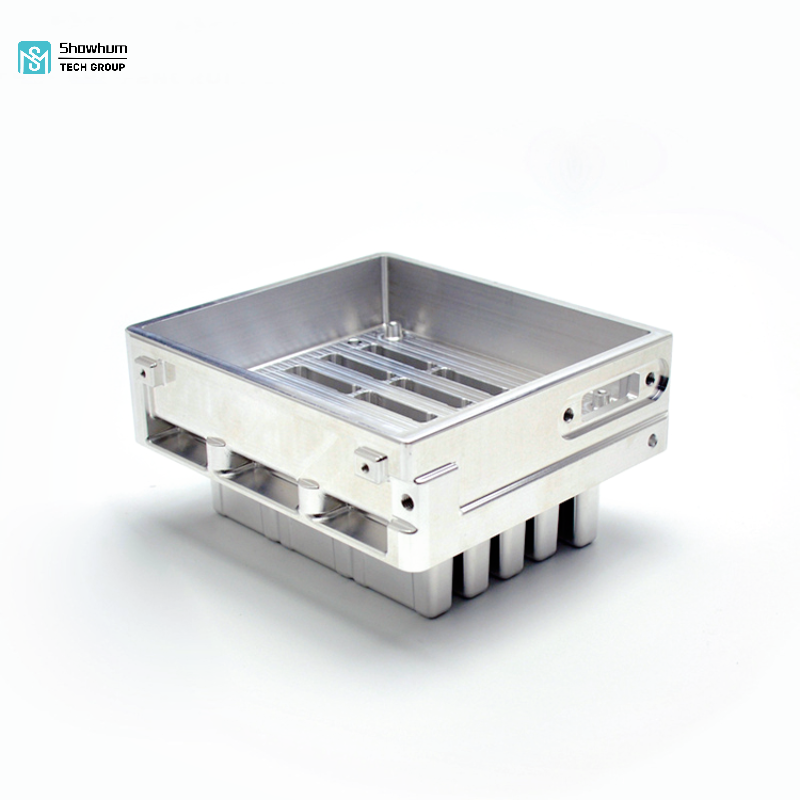

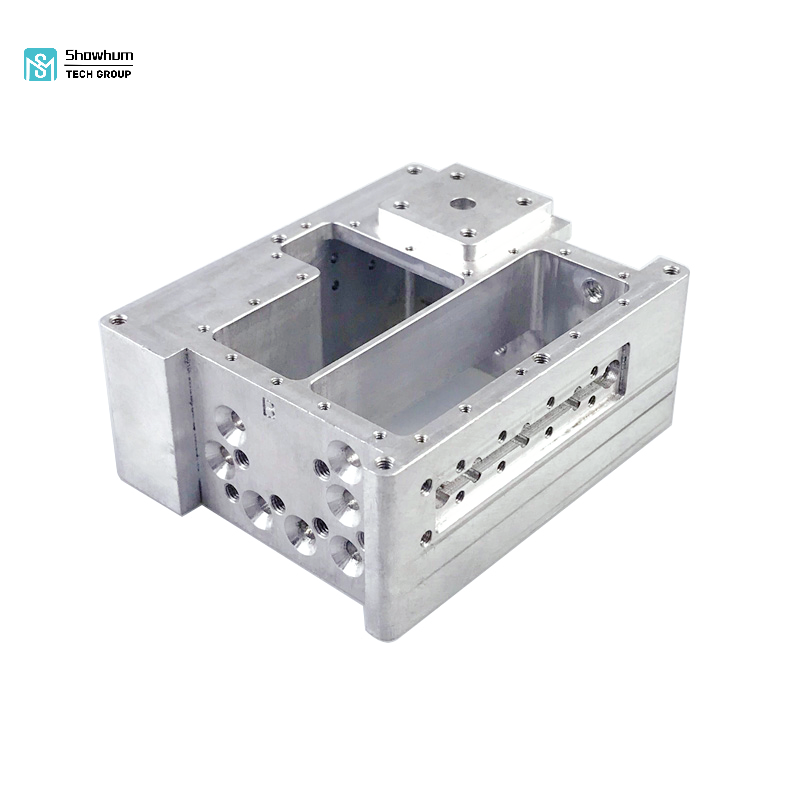

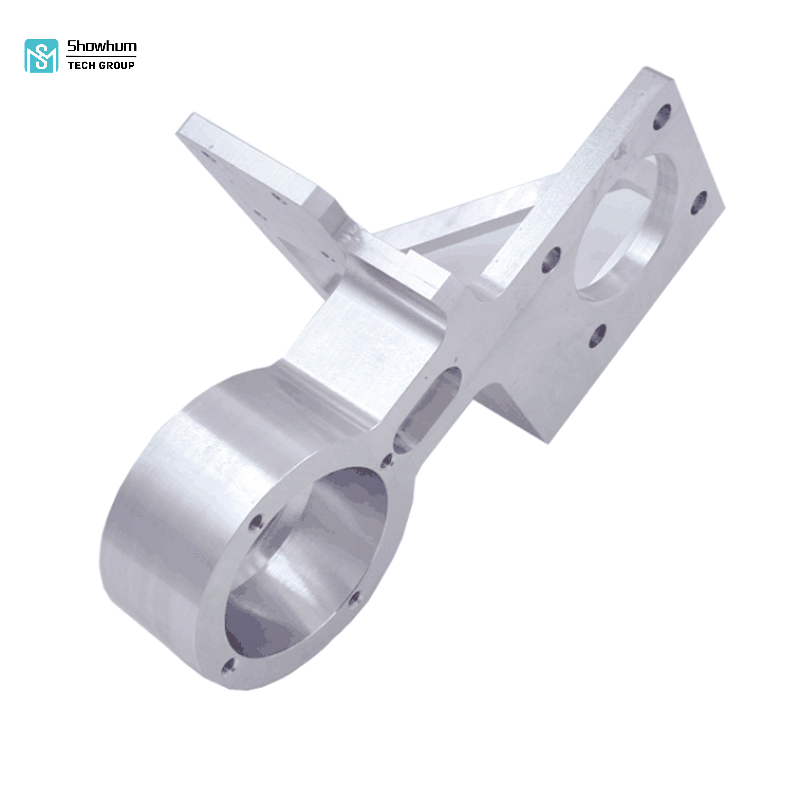

Traditional machining techniques often involve multiple setups and tool changes, which can lead to errors and inefficiencies. 5-axis high-accuracy CNC milling addresses these challenges by offering simultaneous multi-axis movement of the cutting tool. This enables the creation of complex shapes and intricate geometries without the need for multiple setups.

The Power of Precision: Unveiling High-Accuracy Machining

At the core of 5-axis CNC milling lies its ability to achieve a level of precision that was previously unattainable. This technology allows for tight tolerances and exceptional surface finishes, making it suitable for industries that demand uncompromising quality, such as aerospace, medical devices, and automotive components.

Materials at the Forefront: Stainless Steel, Brass, Aluminum, and Titanium

The versatility of 5-axis high-accuracy CNC milling is evident in its application across a range of materials. Stainless steel, known for its durability and corrosion resistance, can be precisely machined to create intricate components for various industries. Brass, valued for its malleability and aesthetics, finds its place in precision instrumentation and decorative pieces.

Aluminum, with its lightweight properties and widespread use, benefits from the precision offered by 5-axis milling. From aerospace components to consumer electronics, this technology enhances aluminum's capabilities. Titanium, renowned for its strength-to-weight ratio, is utilized in critical applications such as medical implants and aerospace structures, where precision machining is non-negotiable.

Advancing Industry Standards: Benefits and Applications

The benefits of 5-axis high-accuracy CNC milling extend beyond precision. Reduced setup times, improved efficiency, and minimized material waste contribute to cost-effectiveness. The ability to create complex shapes and undercuts is invaluable in industries that demand intricate components, such as turbine blades in aerospace engines or medical implants with specialized geometries.

Quality Assurance: Meeting Rigorous Demands

Industries that rely on precision machining demand rigorous quality assurance. 5-axis high-accuracy CNC milling undergoes meticulous testing to ensure adherence to tight tolerances and exact specifications. This level of quality control is essential to producing components that meet the highest industry standards.

Conclusion: Pioneering Precision in Manufacturing

5-axis high-accuracy CNC milling represents the pinnacle of precision machining. With the capability to create intricate designs and components in materials ranging from stainless steel to titanium, this technology transcends traditional machining limitations. As industries evolve and demand increasingly intricate and precise components, 5-axis CNC milling stands as a testament to the innovation that drives modern manufacturing.

#CNCPart #cncmachining #precisionmachining #CustomizedCNC #SheetMetalLaser #CNCAnodizedAluminium #StampingPart #CastingPart #diecastingpart #Forgingprocessing #Bicycleaccessories #Motorcycleaccessories #Motorcycleframe #Bicycleframe #motorcyclesparepart #motorcyclesparepartsparpart@showhum

Email: sales@showhum.com Whatsapp: 08615722792017 Web: www.showhum-techgroup.com