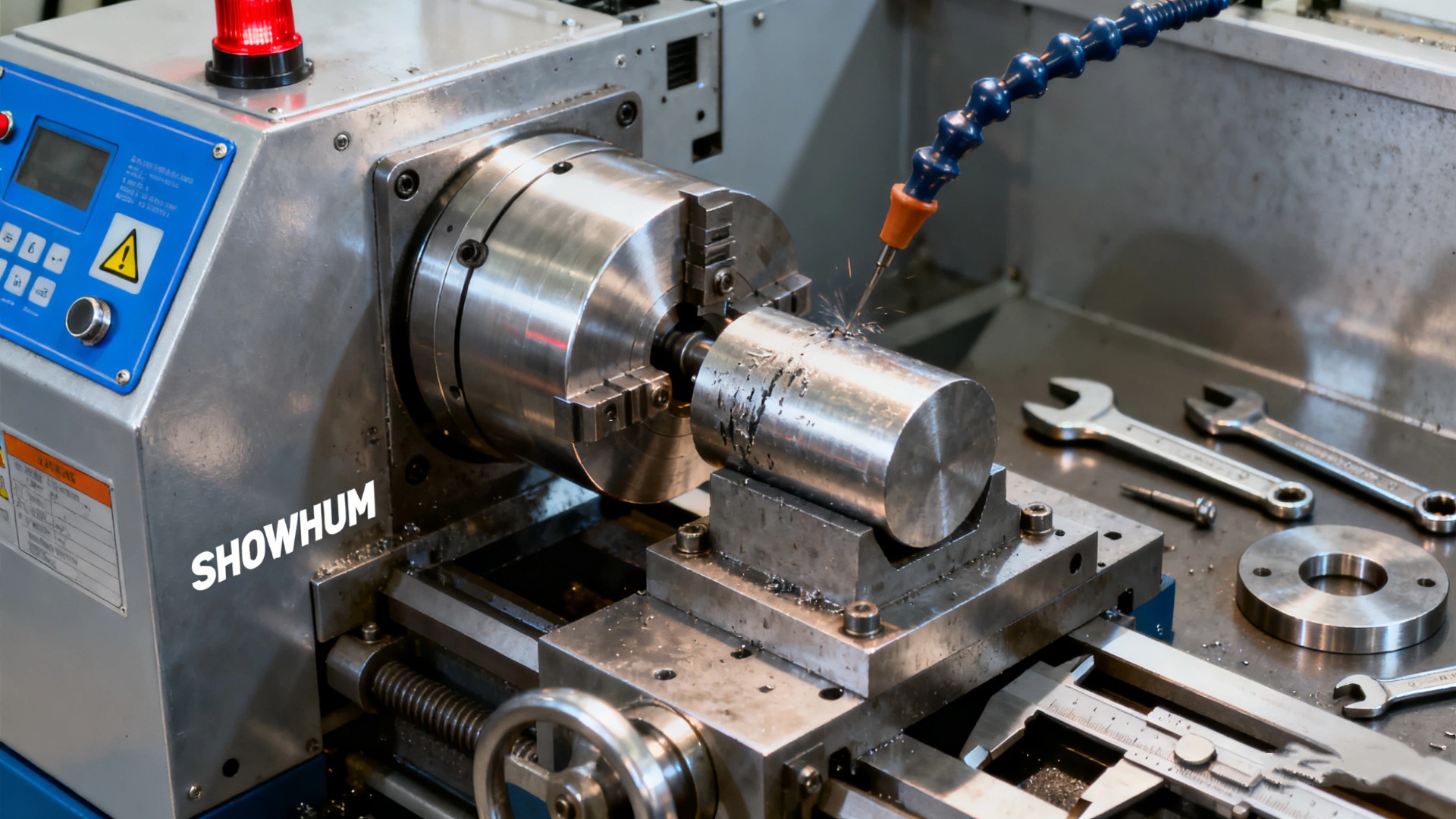

The synergy of CNC machining, welding, laser cutting, and injection molding forms the backbone of modern industrial production. CNC provides unmatched precision for critical components, laser cutting enables rapid, intricate flat patterns, welding creates durable metal assemblies, and injection molding delivers mass-produced plastic parts efficiently.

Their collective advantages – precision, speed, strength, scalability, and material versatility – drive innovation across aerospace, automotive, medical, electronics, and consumer goods. The future outlook is exceptionally bright, driven by trends like automation and Industry 4.0 integration (enhancing speed and consistency), advanced materials (composites, high-performance alloys/polymers), and additive manufacturing complementing these techniques. Sustainability is also a key driver, pushing for energy-efficient processes, waste reduction, and material recycling.

Continuous advancements in these core processes will ensure they remain central to manufacturing, enabling lighter, stronger, smarter, and more sustainable products for decades to come.

#CNCParts #PrecisionMachining #CNCProgramming #Milling#SheetMetalFabrication #MetalBending #LaserCutting #ChassisFabrication#WaterjetCutting #WaterjetArt #AbrasiveJet #CuttingTechnology#TIGWelding #MetalWelding #FabricationWelder #WeldPorn#Anodized #PowderCoating #MetalFinishing #SurfaceTreatment