The family of friction welding processes, encompassing Rotary (RFW), Linear (LFW), and Stir (FSW) variants,

offers distinct advantages that traditional fusion welding struggles to match, driving their adoption into increasingly diverse applications.

The paramount advantage is the solid-state nature of bonding. By generating coalescence through friction-induced heat and plastic deformation *without* bulk melting, FW inherently avoids defects like porosity, solidification shrinkage, hot cracks, and segregation.

This results in joints with exceptional strength, toughness, and fatigue resistance, often superior to the base metal in specific configurations.

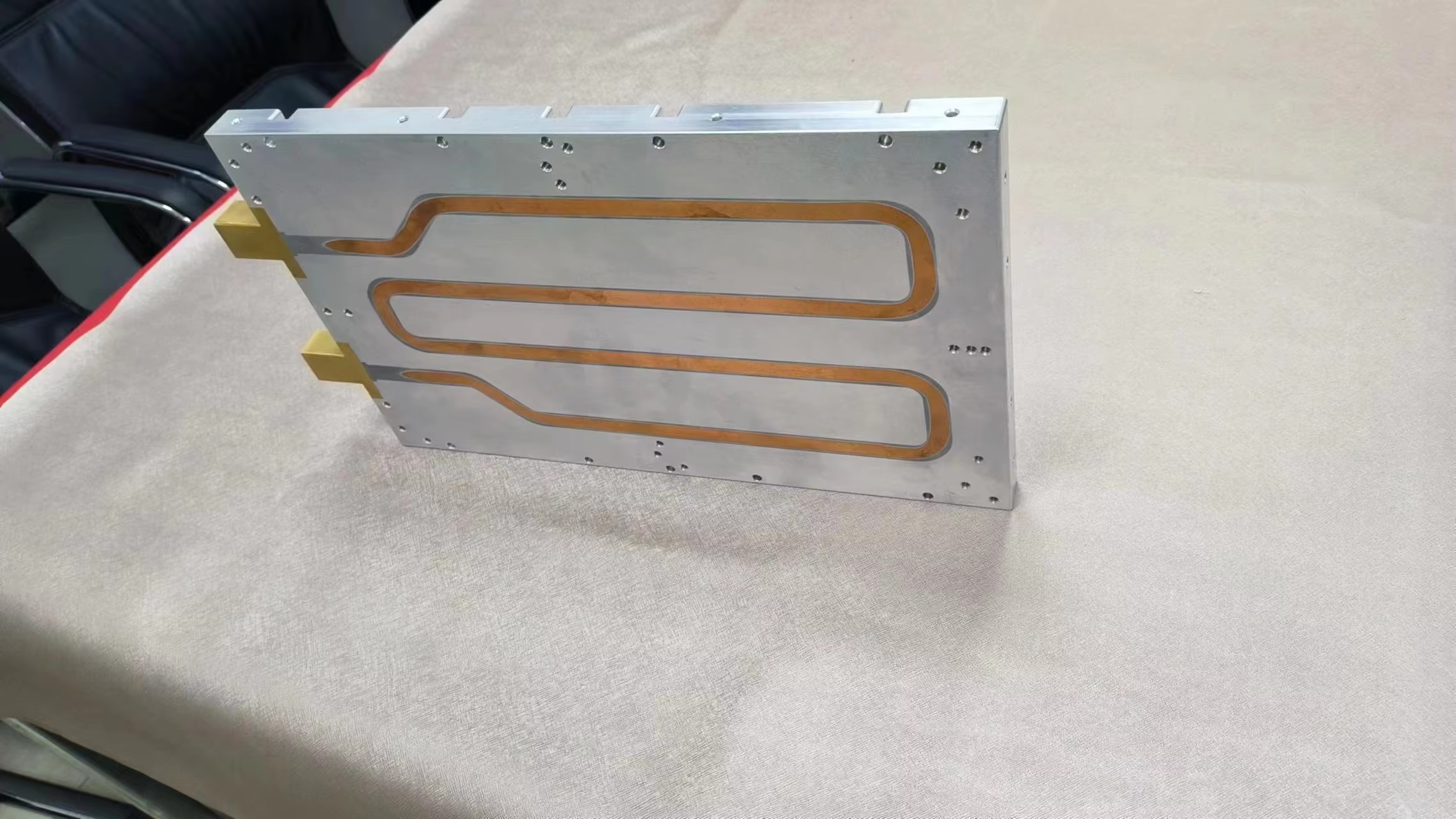

This capability is particularly transformative for joining dissimilar metals (e.g., aluminum to copper for electrical parts, aluminum to steel for lightweighting, titanium to steel) and advanced materials like metal matrix composites (MMCs), where fusion welding often fails due to incompatible melting points or detrimental intermetallic formation.

FW processes are also highly energy-efficient, focusing heat precisely at the joint interface, reducing overall power consumption.

They eliminate the need for filler metals, shielding gases, and flux, minimizing consumable costs and environmental impact (no fumes/spatter). Additionally, FW is highly controllable, repeatable, and ideally suited for robotic automation, ensuring consistent quality in mass production.

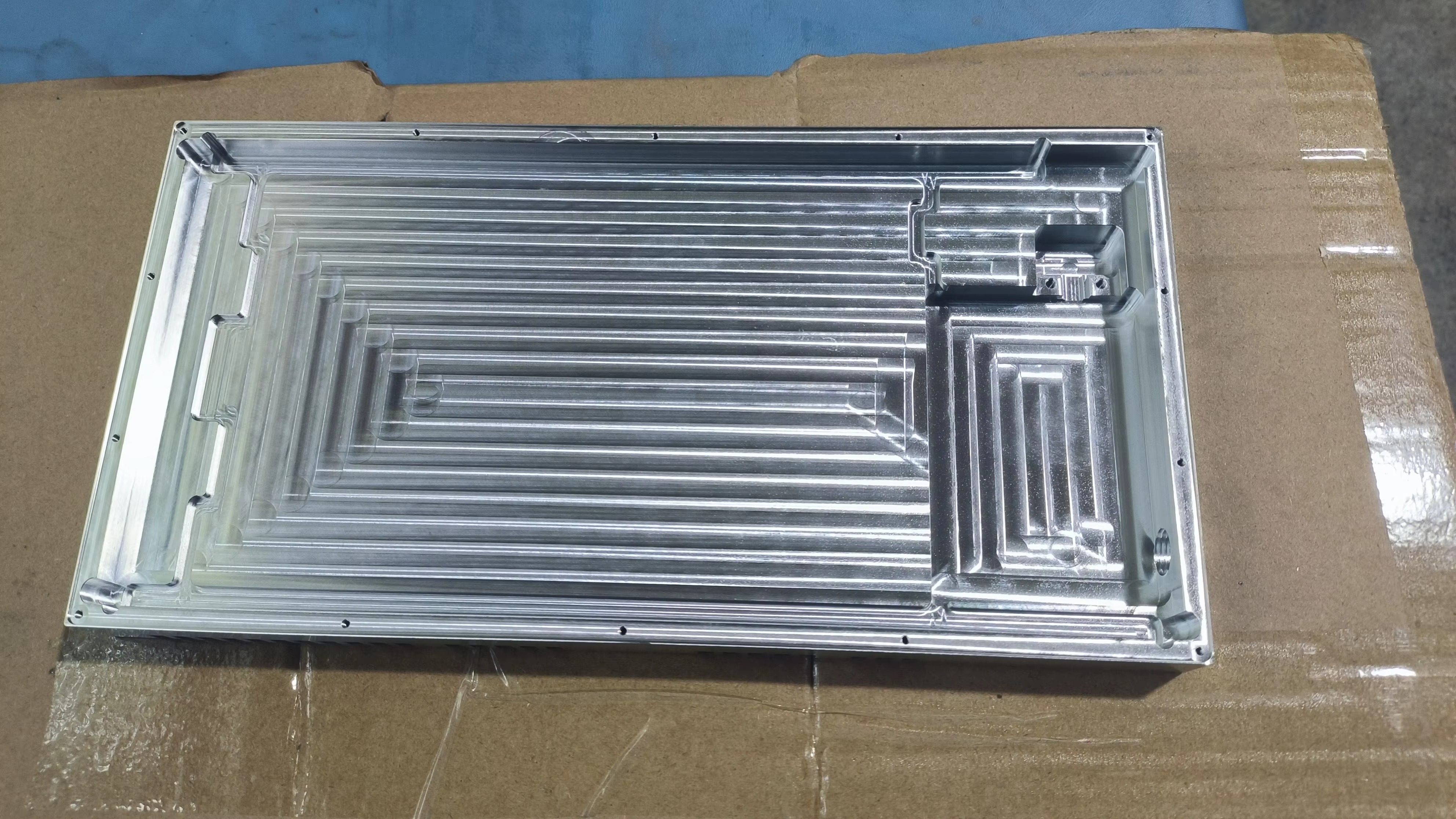

The practical advantages of friction welding translate into critical applications shaping modern industry. **Rotary Friction Welding (RFW)** excels in high-volume production of axisymmetric parts, extensively used for automotive driveline components (axles, transmission shafts, turbocharger shafts), cutting tools (drill bits with carbide tips), pipelines (sucker rods, valves), and electrical contacts. **Linear Friction Welding (LFW)** is the go-to process for non-rotationally symmetric parts under high cyclic loads, predominantly manufacturing blisks (bladed disks) and blade reinforcements for jet engines from titanium and nickel alloys, as well as automotive pistons and turbine blades. **Friction Stir Welding (FSW)** has the broadest reach, revolutionizing the fabrication of large aluminum structures: aerospace fuselages and wings, ship hulls and decks, high-speed train bodies, automotive chassis and battery enclosures, and even architectural panels. Its spot welding variant (RFSSW) is rapidly displacing resistance spot welding in automotive aluminum bodies. Emerging applications include nuclear waste containment and repair of high-value components.

**Summary:** Friction welding technologies (RFW, LFW, FSW) collectively offer a paradigm shift in joining, characterized by solid-state bonding that eliminates fusion defects and enables the welding of challenging and dissimilar materials. Their energy efficiency, environmental friendliness, and automation potential provide significant economic and operational benefits. As a result, friction welding has become essential across high-tech sectors—aerospace, automotive, energy, and transportation—providing reliable, high-performance solutions for critical components and enabling innovations in lightweight design and advanced material utilization, ensuring its continued expansion into new frontiers.