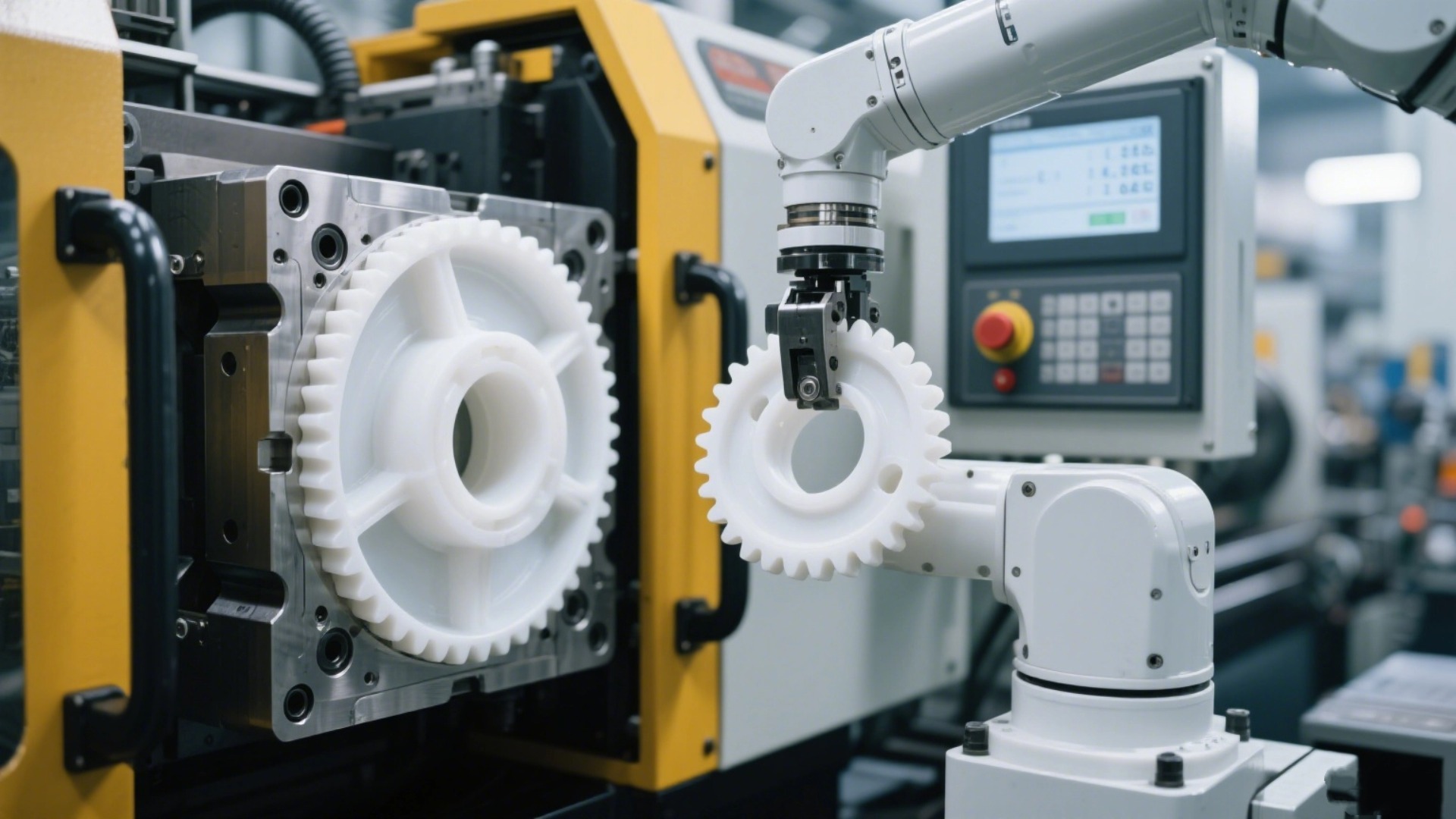

Plastic injection molding is a cornerstone of modern manufacturing, offering unparalleled versatility across a wide range of industries. From automotive and aerospace to consumer electronics and medical devices, injection-molded components are integral to countless products we rely on daily. In the automotive sector, they are used to produce everything from interior panels and dashboards to under-the-hood components, thanks to their durability and lightweight properties. The medical industry depends on sterile, high-precision molded parts for devices such as syringes, inhalers, and surgical instruments. Similarly, consumer goods—including household appliances, toys, and packaging solutions—leverage the efficiency and consistency of injection molding to meet high demand and stringent quality standards. This widespread applicability underscores the process’s adaptability to complex designs and diverse material requirements.

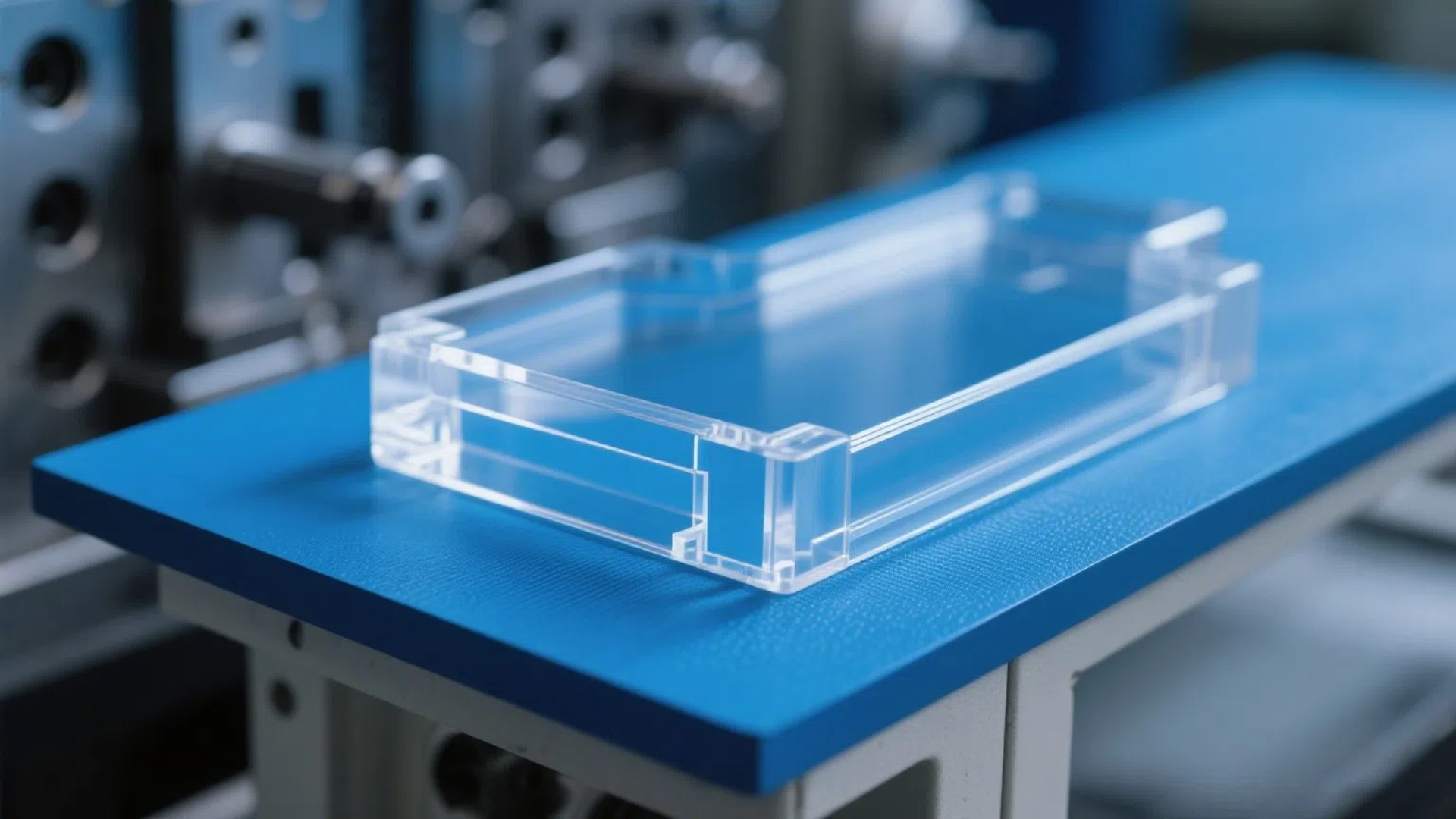

The advantages of plastic injection molding make it a preferred choice for mass production. First, it enables high-volume manufacturing with exceptional efficiency and repeatability, ensuring consistent part quality and reducing per-unit costs. The process supports the use of a vast selection of thermoplastic materials, each offering specific properties such as chemical resistance, high strength, or flexibility. Additionally, injection molding allows for intricate geometries and tight tolerances that would be challenging or impossible to achieve with other methods. Minimal material waste is another significant benefit, as excess plastic can often be recycled and reused. Moreover, once the initial mold is created, production cycles are rapid, facilitating shorter lead times and scalable output to meet market demands.

In summary, plastic injection molding stands as a vital technology driving innovation and efficiency in global manufacturing. Its ability to produce durable, precise, and cost-effective components on a large scale makes it indispensable across sectors. As industries continue to evolve toward lighter, more sustainable, and higher-performance products, injection molding remains at the forefront, adapting to new materials and advanced technologies. For businesses seeking reliable, scalable, and economically viable production solutions, plastic injection molding offers a proven and future-ready path to success.

About Us

We are a professional foreign trade company specializing in high-quality plastic injection molding products. With a focus on precision, durability, and customer satisfaction, we provide end-to-end manufacturing and export services to clients worldwide.